Cut to Length & Multi-blanking Lines

Innovative, cost-effective Cut-to-Length & Multi-Blanking solutions.

CWP© is a member of FORMTEK©, a "best-of-class" group of manufacturers dedicated to improving the productivity of forming precision products from coiled metal. Cut to Length Lines manufactured by Formtek Maine companies B&K©, CWP©, IPI© and Rowe© give manufacturers, service centers and job shops a productivity edge. For more than 70 years we have led the way with design innovations for the coil metal processing industries. We are proud of our ability to produce Cut to Length lines and Multi Blanking Lines that provide greater productivity, easier setup, automated stacking and material handling, faster changeovers and tight tolerances for better quality parts. Our Cut to Length/Multi Blanking Lines can produce blanks with length and width tolerances of ±.005" |

||

|

» Critical Finish CTL » High Speed CTL Lines » Multi-Blanking Lines » Spacesaver CTL Lines » HD ¼" Thick CTL Lines » Narrow Width CTL Lines Download the PDF Brochure  Cut to Length Systems

[5.40 MB] Cut to Length Systems

[5.40 MB] |

|

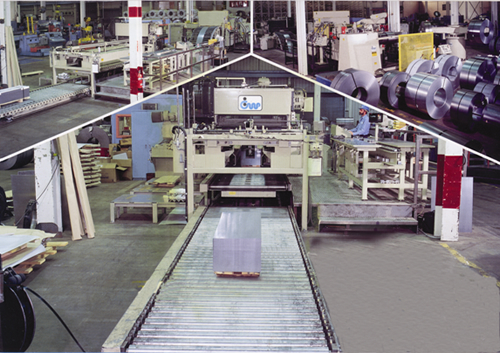

High Speed Cut To Length Line capable of producing blanks at a rate of 100 SPM at a 24" length and 30 SPM at a 120" length

This Cut to Length line was provided for a major appliance manufacturer to solve the issue of supplying formed refrigerator door blanks for down-line supply. Equipped with a four-post 120-ton hydraulic press for in-line notching and punching, and a traveling cutoff shear, the fully integrated system control platform makes easy work of providing the required formed blanks. The finished parts are conveyed through the inspection area from the exit of the press and into the 120" stacker. A combination direct drop and air blower within the stacker ensures that the sheets float into position and prevents any chance of marking the critical surface material. A B&K© 60" 1.156 Precision Corrective Leveler was integrated into this CWP© Line to produce first operation leveled blanks directly from coil. Leveled parts that can be produced on this type of system range from refrigerator doors (shown in picture above), washer and dryer panels to commercial or residential doors.

72" wide coils up to .125" thickness can be processed on this Cut To Length Line manufactured for the Bluebird Bus company. A precision B&K© Leveler is incorporated to allow production of panel flat blanks, while a 4-Roll Servofeeder and Hydraulic Shear with camber compensation adjustment, guarantee precise accuracy and squareness.

72" Double Uncoiler provides quick coil changeover while the Turnstile and Coil Car tandem helps load coils quickly and efficiently.