HD ¼" Thick CTL Lines

Powerful, Rugged CWP© HD ¼" Cut-to-Length solutions. |

||

|

||

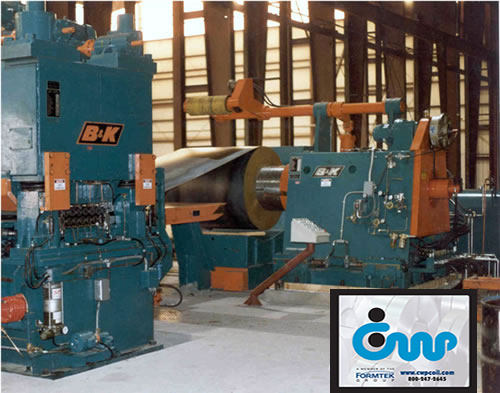

Heavy Duty ¼” Cut to Length Lines by CWP© feature a Series 6/4 precision Coil Straightener ( B&K© Leveler optional) and an exclusive 4-Roll Servofeeder to enhance production. The results are better quality blanks produced at higher production rates. Cut to length lines manufactured at the Formtek Maine facility, produce uniform shear blanks of varying lengths while minimizing scrap. Producing high quality blanks in house can often generate rapid paybacks versus buying blanks. Our 250 series of Cut to Length Lines, also known as Blanking Lines, and Shear Lines can be designed for any combination of material, coil weight, and thickness.

This Cut to Length (CTL) coil handling line provides high productivity and repeatable accuracy for a steel service center. The system features a heavy-duty direct drop part stacker and pallet transfer system to expedite material flow. This high-productivity cut to length line also features a hydraulic bow-tie shear, 4-roll servo feed with automated control, pneumatic threading table, power driven precision coil straightener with powered head adjustment via job number, hold-down peeler system, 30,000 Lb. uncoiler and coil loading car.

30,000 Lb. coils up to .250" thickness can be processed on this 72" wide Cut to Length Line. This line, developed for a major service center, features a 240" stacker and transfer system. Equipped with a 4-roll servofeed for accuracy of +/- 0.002" which allows the machine to decrease roll pressure by 50% while increasing the traction surface by 100%. The feed system leaves critical surfaces of stainless steel and aluminum unaltered. The line also includes a CWP©-exclusive, auto-ready and diagnostic system allowing one person to operate and maintain the machine.

40,000 Lb. coils up to .250" thickness can be processed on this 72" wide Cut to Length Line. This cut-to-length system solution for a major service center is designed for high performance and accuracy. The line features a 20' stacker, pallet transfer system and four-roll servofeed allowing for +/- .002" accuracy. Equipped with heavy-duty debender, knurled thread-up rolls, chrome rolls, ultrasonic variable tension brake control. Exclusive "Auto-Ready" and diagnostic system allows hands-free thread-up and processing of 72" x .250" surface critical material by one operator.

A B&K© Precision Corrective Leveler can be installed in your new Cut to Length Line or retrofitted into an existing Cut to Length Line to precisely control flatness of your finished parts. Precision Levelers are much better at removing coil set and crossbow than coil straighteners or coil flatteners. Precision Corrective Levelers can also eliminate shape defects such as center buckle and edge wave in coil strip by selectively bending the work rolls. B&K© Corrective Levelers utilize a series of relatively small closely spaced leveler rolls that incorporate roller back-ups to prevent deflection. This arrangement allows the material to be worked beyond the yield point to remove trapped material stresses. The result is material that is more stable so that part quality is consistent. The material thickness range and the material yield point determine the Roller Leveler work roll diameter.