Multi-Blanking Lines

Innovative, cost-effective Cut-to-Length & Multi-Blanking solutions. |

||

|

|

|

Multi-blanking lines manufactured in the Formtek Maine facility incorporate the best design ideas from IPI©, B&K©, Rowe© and CWP©. These Multi blanking machines are designed to provide finished slit blanks or sheets from coiled stock. The coil stock can be edge trimmed by the slitting section to obtain a precise width or slit to provide multiple precision blanks. A powered coil straightener to flatten the coiled stock or a Precision B&K© Corrective Roller Leveler for precise leveling of the material is incorporated into the line. While a production shear assembly cuts the material to length.

This Multi-Blanking Line can produce blanks from 50,000 LB. coils that are up to 60"(1500mm) wide and .12"(3mm) thickness. A slitter blade position indicator makes setup fast and accurate.

40,000 Lb. coils up to .125" thickness can be processed on this 72" wide Multi-Blanking Line. A precision B&K© Leveler is incorporated to allow production of panel flat blanks.

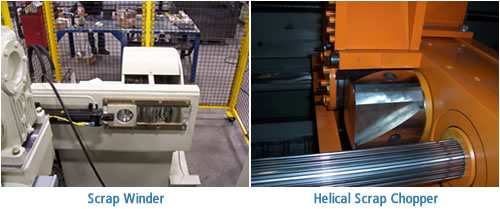

A 4-Roll Servofeeder, Heavy-duty Slitter and Hydraulic Shear ensure high quality precision blanks. The Direct Drop Sheet Stacker is ideal for critical finished materials and can be quickly converted to a Multi-Blanking Stacker. Edge trimmed material can be wound up on our scrap winder or chopped up in our Helical Scrap Chopper.