Compact Coil Systems

|

COMPACT COIL LINES

Designed for maximum productivity within a minimum amount of space |

|

Compact Coil Lines by CWP are designed specifically to handle coil stock in a space-saving footprint. The Compact Coil Line incorporates a motorized uncoiler, servo controlled straightener/feeder and an optional coil-loading car. The Compact Coil Line shown above incorporates a servomotor driven pilot release for the upper straightener rolls. The key advantages are; high speed operation (up to 100 spm), accurate roll lift timing and reduced air consumption. This compact coil line provides coil material loading, uncoiling, straightening and feeding while only requiring 16' of floor space. Because the material is straightened at the entrance to the press with a CWP Compact Coil Line, the use of a loop pit providing slack material becomes unnecessary. The length of the line is shortened and thread-up and recoil times are noticeably reduced. A CWP Compact Coil Line can also help reduce material scrap and reduce downtime. As a coil of material is depleted during operation, the coil set increases as the OD decreases. This change in coil set may require deeper roll penetration to produce an acceptable flat part. The straightener section is located right in front of the press. Therefore, adjustments to the straightener improve the quality of the part almost immediately reducing material jams and scraped parts. Material that is 5/16" thick can be processed on this 30" wide compact coil line. A touch screen interface with the thread-up manual and maintenance manual as well as system diagnostics are all available at your fingertips on the integrated touch screen. 3 Powered rider rolls insure maximum control during thread-up while a double uncoiler with powered index ensures quick coil changeover. |

|

|

|

Formtek-Maine (CWP) manufactures many different configurations of compact coil handling systems to fit virtually any need or specification. The compact coil line shown at left consists of a powered coil reel / stock reel and ServoMax servofeed with "pull-through" straightener. This compact press feed system can handle material that is 12" wide with a thickness of .125" from a 6,000 lb. coil. |

|

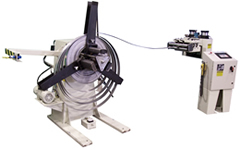

This compact coil line features a dual operation mode to allow both top or bottom payoff of coiled material. The capacities of this compact coil system allow material of 24" wide, .125" thick from 10,000 lb. coils. The straightener feeder is also equipped with a pneumatic roll release. |

|

|

|

|

|

24" wide material that is ¼" thick can be processed on this line. Top or bottom payoff along with a touch screen interface are the main features of this space saving powerhouse. The thread-up manual and maintenance manual as well as system diagnostics are all available at your fingertips on the integrated touch screen. |

| The compact cradle and straightener-feeder shown at right can safely process ¼" thick material up to 12" wide all the way down to a minimum width of 1". This compact coil system can handle 10,000 lb. coils, 24" wide at .156 inches thick. |  |