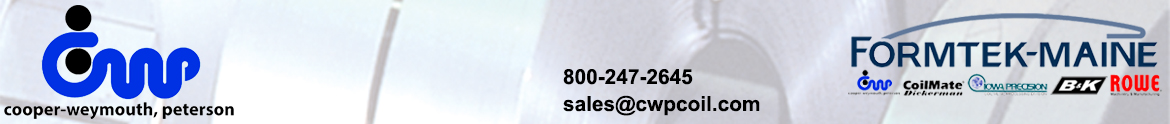

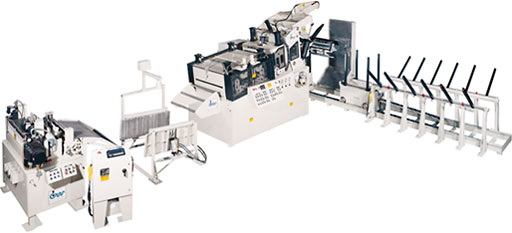

Coil Processing Systems

Press Feeding Systems

Innovative, cost-effective coil processing solutions. CWP© has designed and built coil processing systems to accommodate stock up to 84" wide, .500" thick and coils weighing up to 80,000 lbs. Shown here are representative coil processing solutions from the hundreds of systems we have built for major manufacturers in the appliance, automotive, lighting, metal furniture, HVAC and contract job shop industries.  High Volume Progressive and Transfer StampingsHigh capacity, 36" x .250" x 20,000 lb. integrated system solution for a major manufacturer specializing in high volume progressive and transfer stampings for the electric motor, lawn and garden, recreational vehicle, food service and automotive industries. The line features an extra high capacity electronic feed, coil staging rack and coil car for automatic coil loading and fast, easy changeovers.  Automotive System SolutionHeavy-duty, integrated system solution built for a major, tier one automotive supplier. The 72" wide x 40,000 lb. x .125" line features a double spindle payoff reel design that increases productivity by allowing one side to be loaded while the other side is paying off stock. The double spindle design provides significant savings in coil loading time, especially when partial coils are utilized on a regular basis.  Large Capacity Contract StampingA leading contract stamping company produces a variety of parts with this 72" x .125" x 50,000 lb. automated system solution. The large capacity integrated system features heavy-duty turnstile with 360° rotation and coil car providing efficient staging of coils and automated coil loading and unloading for just-in-time production demands.  System Solution for Automotive Brake Parts ManufacturerRugged, 60" x .500" x 40,000 lb. system solution features a space-saving, combination straightener-feeder and heavy duty debender that significantly reduces set-up time by aiding the operator in threading the leading edge of thick (up to .500") coils and high yield materials. |