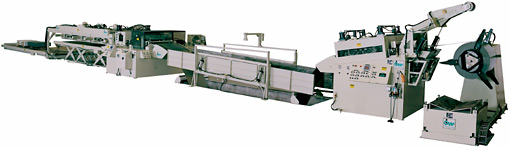

Cut-to-Length Systems

|

CWP© cut-to-length and blanking systems incorporate a variety of coil loading options, mechanical or hydraulic shears and pneumatic or servo drop stackers. The cut to length lines shown are representative of our capabilities designed to provide C-T-L system solutions that offer greater productivity easier set-up, faster changeovers and accurate part quality for major service centers and a variety of industries and manufacturers.

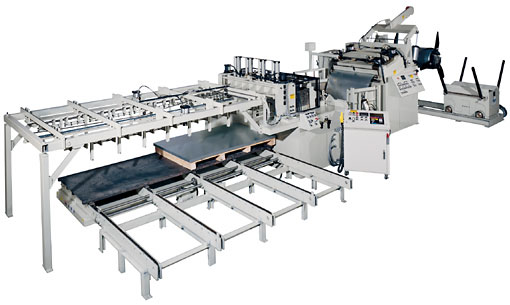

Cut-To-Length Space-Saving Solution This 48" x .093" x 20,000 lb. Cut to Length (CTL) coil handling line provides high productivity and repeatable accuracy for a major electronics manufacturer. The system features a heavy-duty pneumatic part stacker and pallet transfer system to expedite material flow. This high-productivity cut to length line also features a hydraulic bow-tie shear, 4-roll servo feed with automated control, pneumatic threading table, power driven stock straightener with powered head adjustment via job number, hold-down peeler system, 6.5R stock reel and coil loading car. View additional Cut-to-Length images |