ServoMax© V Servo Feeds

The ServoMax© V, two-roll and four-roll advanced servo feeds continue to deliver enhanced features over the competition. CWP© Servo Feeds deliver an unparalleled level of refinement, including increased job memory and torque output for heavier capacity or increased production requirements. ServoMax© V control systems can also be adapted to most existing servo driven roll feeders. Optional models include a programmable pattern ServoMatrix©, the optical sensor based ServoSensor©, and the SpeedMatic© which is electronically geared to the motion of the press for greater flexibility and performance. The ServoMax© V, two-roll and four-roll advanced servo feeds continue to deliver enhanced features over the competition. CWP© Servo Feeds deliver an unparalleled level of refinement, including increased job memory and torque output for heavier capacity or increased production requirements. ServoMax© V control systems can also be adapted to most existing servo driven roll feeders. Optional models include a programmable pattern ServoMatrix©, the optical sensor based ServoSensor©, and the SpeedMatic© which is electronically geared to the motion of the press for greater flexibility and performance. |

|

Standard Features:

|

|

Options:

|

|

Specifications

ServoMax© V - Standard Duty Servo Feeds

2.75" Roll Diameter

Mechanical Features:

|

| Model | Max. Stock Width | Capacity Full Width | Feed Length | SMXV6 | 6" (152.400mm) | .187" (4.750mm) | 999.999 (25.39m) |

|---|---|---|---|

| SMXV12 | 12" (304.800mm) | .156" (3.962mm) | 999.999 (25.39m) |

| SMXV18 | 18" (457.200mm) | .125" (3.175mm) | 999.999 (25.39m) |

| SMXV24 | 24" (609.600mm) | .093" (2.362mm) | 999.999 (25.39m) |

| SMXV30 | 30" (762.000mm) | .078" (1.981mm) | 999.999 (25.39m) |

| SMXV36 | 36" (914.400mm) | .062" (1.575mm) | 999.999 (25.39m) |

ServoMax© V - High Capacity Servo Feeds

4" Roll Diameter

Mechanical Features:

|

| Model | Max. Stock Width | Capacity Full Width | Feed Length | SMXV12H | 12" (304.800mm) | .250" (6.350mm) | 999.999 (25.39m) |

|---|---|---|---|

| SMXV18H | 18" (457.200mm) | .187" (4.750mm) | 999.999 (25.39m) |

| SMXV24H | 24" (609.600mm) | .187" (4.750mm) | 999.999 (25.39m) |

| SMXV30H | 30" (762.000mm) | .156" (3.962mm) | 999.999 (25.39m) |

| SMXV36H | 36" (914.400mm) | .125" (3.175mm) | 999.999 (25.39m) |

| SMXV42H | 42" (1066.800mm) | .093" (2.362mm) | 999.999 (25.39m) |

| SMXV48H | 48" (1219.200mm) | .078" (1.981mm) | 999.999 (25.39m) |

ServoMax© V - Heavy Duty Servo Feeds

6" Roll Diameter

Mechanical Features:

|

| Model | Max. Stock Width | Capacity Full Width | Feed Length | SMXV12H6 | 12" (304.800mm) | .375" (9.525mm) | 999.999 (25.39m) |

|---|---|---|---|

| SMXV18H6 | 18" (457.200mm) | .328" (8.331mm) | 999.999 (25.39m) |

| SMXV24H6 | 24" (609.600mm) | .281" (7.137mm) | 999.999 (25.39m) |

| SMXV30H6 | 30" (762.000mm) | .265" (6.731mm) | 999.999 (25.39m) |

| SMXV36H6 | 36" (914.400mm) | .250" (6.350mm) | 999.999 (25.39m) |

| SMXV42H6 | 42" (1066.800mm) | .218" (5.537mm) | 999.999 (25.39m) |

| SMXV48H6 | 48" (1219.200mm) | .187" (4.750mm) | 999.999 (25.39m) |

| SMXV54H6 | 54" (1371.600mm) | .171" (4.343mm) | 999.999 (25.39m) |

| SMXV60H6 | 60" (1524.000mm) | .156" (3.962mm) | 999.999 (25.39m) |

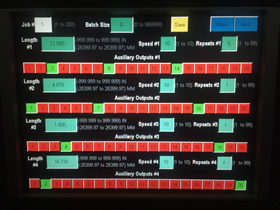

ServoMatrix© The ServoMatrix feed control system is ideal for applications requiring multiple feed lengths within a pattern. Programmable outputs can be set up to energize during the move for flexible gag dies or at the end of the move for punching and notching stations. Additional programmable outputs can be added as an option. Operator defined batch count can be used to track the part count while the fed is in automatic mode. Available on all CWP two-roll and four-roll feed systems. The ServoMatrix feed control system is ideal for applications requiring multiple feed lengths within a pattern. Programmable outputs can be set up to energize during the move for flexible gag dies or at the end of the move for punching and notching stations. Additional programmable outputs can be added as an option. Operator defined batch count can be used to track the part count while the fed is in automatic mode. Available on all CWP two-roll and four-roll feed systems. |

|

|

|

Standard Features:

|

ServoSensor© The ServoSensor feed control system is ideal for any application requiring precise accuracy of a pre-printed surface. It allows accurate material positioning through precision feedback from an optical sensor. The ServoSensor control allows the operator to program a given feed length as a basis for the move, whereby the feed moves the given distance and then "looks" for input from the sensor based on preprogrammed contrast. The ServoSensor feed control system is ideal for any application requiring precise accuracy of a pre-printed surface. It allows accurate material positioning through precision feedback from an optical sensor. The ServoSensor control allows the operator to program a given feed length as a basis for the move, whereby the feed moves the given distance and then "looks" for input from the sensor based on preprogrammed contrast.

Available on all CWP two-roll and four-roll feed systems. |

SpeedMatic© The SpeedMatic feed control system features a roll feeder motion that is electronically geared to the motion of the press or shear for maximum flexibility and performance. The controller utilizes a signal from a press- or shear-mounted resolver to determine the acceleration speed of the servo feeder. All feeder and roll release motions are positionally defined and electronically linked to the press or shear position. Speed of the servo feeder is automatically adjusted as the press speed is adjusted. The result is very smooth velocity profile at any press speed. The controller can be adapted to most existing servo driven roll feeders. The SpeedMatic feed control system features a roll feeder motion that is electronically geared to the motion of the press or shear for maximum flexibility and performance. The controller utilizes a signal from a press- or shear-mounted resolver to determine the acceleration speed of the servo feeder. All feeder and roll release motions are positionally defined and electronically linked to the press or shear position. Speed of the servo feeder is automatically adjusted as the press speed is adjusted. The result is very smooth velocity profile at any press speed. The controller can be adapted to most existing servo driven roll feeders. |

|

|

|

Standard Features:

|

|